Hairdyer can make hair dry quickly and beautifully

Basic theory

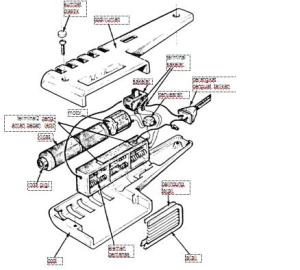

A hairdryer airplane has three main parts: a motorcycle, a heating element and fan. When the rotating plane, carrying hot heating element and a fan blowing hot air flow out through the bars of the elements. Switches that operate aircraft having one or more positions. Some hair dryers have multiple switches, a motor controller and a controller or two heating elements. Many hairdryer is placed in a plastic house seal; This house can not be disassembled for repair. If the aircraft does not work, take it to a professional service aircraft. Estimate the cost of repairs before the specified improvements; how much it cost to replace it with a new aircraft when compared to fix it.

Caution: Before doing some work on the hair dryer, make sure that the plug has been detached plane.

Cleaning and Lubrication

Components in the hairdryer collect a lot of dirt; when the aircraft rotates, dust and hair sucked enter the inlet air stream. Take it apart and the periodic component parts, and check the terminal on the unit. If the terminal on fire, dirty, or corroded, clean them with steel wool (steel wool) Good and soft cloth. Remove hair and dirt from all parts. Clean the motor shaft and bearing fan that spins, and lubricate these parts with a clear oil Household - Sewing machine oil is also good.

When you clean the plane, check switch ON / OFF and, if the aircraft have it, the controller switches the heating element. Clean and tighten the switch terminals. If the switch is clogged dirt, disconnect the end of the wire to it and remove dirt from the switch. Spray terminal switch with electrical contact cleaner, can be obtained (available) in the aircraft repair and supplier of electrical components. Return the switch to normal and so on while insert cleaner on the moving parts, and rub with a soft cloth to clean it; then reinstall.

heating More

Because of the heat generated by the elements is very high, the aircraft has a safety overload, which will turn off the heating element when the round heat generated is too high. If the aircraft stops spinning when in use, disconnect the power source to the aircraft and allow aircraft to cool for 30 minutes or more; Please check again later. If the aircraft works, the problem is more simple heat; Safety thermal overload has been decided and, as the plane is cold, it will reset itself. If the aircraft does not work after cooling for 30 minutes, safety loads more - in many ways is the thermostat thermodisc (chip-hot) - usually placed on the heating element. Look for the section curves and convex on the bimetallic with a diameter of about 1 inch.

To determine the safety overload again broken, Test it by AVO, set on RX1 scale; meter will point to zero. If the load is damaged safety, replace with a new one that is similar. Remove the old one, and connect the new security in the same way as the old connection.

Heating element

Some hair dryers have a heating element; some have 2 elements. If the plane died when in use, and a safety overload is not damaged, the problems usually occur damage to the heating element. Open plane and test elements. If the element is damaged, loose, or hanging, it must be replaced. Replace it with a new element similar. Remove the screws that hold the old elements, the electrical disconnect and remove the old element. If the old element can not be disassembled from its place, take a plane to a professional service, or, if the aircraft is not expensive, replace it with a new one.

switches

Many hair dryers have a switch ON / OFF control of the motor and one or two additional switch - if there are 2 heating elements, it is possible there are 2 switch - a set position on the heating element. This switch is usually connected series; if the motor does not rotate because the switch ON / OFF does not work, the element will not heat. If the motor spins but no heat coming out, the controller switches the heating element may be damaged. If the elements of the two plane elements are not too hot, check the overload safety measure before testing the switch element.

Switch often does not work because dirty. If the motor does not spin or the element is not hot, clean the switch with contact cleaner, as described above. If the problem is not solved, and if the heating element and the motor does not not damaged, Test it switches to the AVO, set on RX1 scale, the meter should read zero. If the switch is damaged, replace it with a new one that is similar. Connect the new switch in the same way as the old connection.

fan

If the hair dryer can not exhale completely, or if he can not produce hot air in sufficient quantities, may be bound for dirty fan or hair coiled coils on the fan blade. Take it apart and clean the aircraft and the motor shaft bearing fan rotation. Lumasilah this section with a light oil Household - Sewing machine oil is also good. Rotate the fan by hand to test it. If the fan can not rotate easily, replace the fan with a new one that is similar. Remove the old fan with the release bearing and fan pulley on the motor shaft. Place the new fan on the motor shaft and connect in the same way as the old connection; then replace the pads.

If the fan is not attached, the fan blade Test it; blade made of metal or plastic. Metal fan blades can be bent; bend properly so it can be returned to normal with pliers. If there is a curved blade, replace the fan as described above. Plastic fan blade may break or destroyed; if the blade is damaged, replace the fan with a new one that is similar.

Motor

If the motor does not rotate, aircraft loading and turn the motor shaft by hand. If it is too hard to spin, lumasilah RT motor with light oil - also good sewing machine oil. Rotate the shaft to spin freely again. Sometimes the aircraft will rotate normally and then suddenly start blowing cold air; This is caused by the slow rotation of the motor. Dust and hair that is carried by the flow of air inside the plane can continue to enter the motor bearing, slow rotation of the motor and cause more heat and stopped. Remove the fan and bearings, and clean the fan, bearing, and shaft of the motor. Then reassemble the parts.

If cleaning and lubrication can not make the motor spin, if the motor can not be rotated by hand, or if the motor hard, take a plane to the professional service.

Place the new fan on the motor shaft and connect in the same way as the old connection; then replace the pads.

If the fan is not attached, the fan blade Test it; blade made of metal or plastic. Metal fan blades can be bent; bend properly so it can be returned to normal with pliers. If there is a curved blade, replace the fan as described above. Plastic fan blade may break or destroyed; if the blade is damaged, replace the fan with a new one that is similar.

Motor

If the motor does not rotate, aircraft loading and turn the motor shaft by hand. If it is too hard to spin, lumasilah RT motor with light oil - also good sewing machine oil. Rotate the shaft to spin freely again. Sometimes the aircraft will rotate normally and then suddenly start blowing cold air; This is caused by the slow rotation of the motor. Dust and hair that is carried by the flow of air inside the plane can continue to enter the motor bearing, slow rotation of the motor and cause more heat and stopped. Remove the fan and bearings, and clean the fan, bearing, and shaft of the motor. Then reassemble the parts.

If cleaning and lubrication can not make the motor spin, if the motor can not be rotated by hand, or if the motor hard, take a plane to the professional service.

|

problems

|

Possible Causes

|

solving

|

| Plane does not rotate | 1. No daya2. POWER3 cable damage. Switch ON / OFF kotor4. Switch ON / OFF rusak5. Kotor6 switch elements. Rusak7 switch elements. Motor damaged | 1 Check the power cord, plug, and KK. Check-safety lawyer melting or CB on the main panel; perba-kirangkaian.2. Test it cable; if damaged, gantilah3. Clean switch ON / OFF4. Test switch ON / OFF; if damaged, gantilah5. Clean the switch element of switch elements 6 tests; if damaged, replace 7 Bring to a professional service, or replace plane. |

| voltage plane | 1 The power cable is damaged, 2 Electrical system hu-man short. |

1 Test cable; replace if damaged, 2. Bring to a professional service |

| Hot air but the fan does not spin | 1 fan dirty; fans need lubrication, 2 motor shaft needs to be lubricated, 3 Motor defective | 1 Clean and lumasilah fan, 2 Lumasilah motor shaft and sleepers, 3 Bring to a professional service or replace aircraft. |

| Fans spin but the aircraft is not hot | 1 switch element is dirty, damaged 2 switch element, 3 switch ON / OFF the dirty, 4 switch ON / OFF damaged, 5. Safety lebihrusak load, 6 faulty heating element. | 1 Clean the switch element, 2 Test it switch element; if broken, replace, 3 Clean the switch ON / OFF, 4 Test it switch ON / OFF; if broken, replace, 5. Test it loads more safety; if broken, replace, 6 Replace the heating element, or replace aircraft. |

No comments:

Post a Comment